In countless industrial facilities, everyday dust can become a hidden explosive hazard. If your process generates or handles fine particles, a Dust Hazard Analysis (DHA) isn’t just a best practice. It’s a critical, life-saving requirement mandated by safety standards. At Suppression Systems, Inc. (SSI), we provide expert, code-compliant Dust Hazard Analysis services that precisely identify, evaluate, and mitigate combustible dust explosion risks in your facility.

Our certified professionals deliver thorough assessments, helping you achieve compliance with stringent NFPA 652 and NFPA 660 requirements, avoid costly OSHA citations, and safeguard your employees and valuable assets. We’re dedicated to transforming potential hazards into manageable risks, ensuring your facility is not only safe but also fully compliant.

Discover more about our company’s mission and values on our About SSI page.

Why a Dust Hazard Analysis (DHA) is Critical for Your Industrial Facility

A DHA is more than just a regulatory checkbox; it’s a foundational element of a robust safety program. Neglecting a proper combustible dust DHA can lead to devastating consequences:

Proactive Safety: A DHA helps you identify potential ignition sources and dust accumulation points before they become critical threats.

Regulatory Mandate: The National Fire Protection Association (NFPA) standards, primarily NFPA 652: Standard on Combustible Dusts and NFPA 660: Standard for Fire and Explosion Prevention of Hazardous Materials, explicitly require a DHA for facilities handling or processing combustible dusts. OSHA also actively enforces these standards through its Combustible Dust National Emphasis Program (NEP), leading to significant fines and penalties for non-compliance.

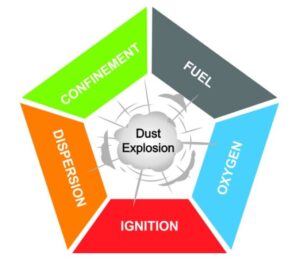

Catastrophic Risks: Industrial processes involving combustible dust (like flour, sugar, wood, metal powders, plastics, and chemicals) can result in primary and secondary dust explosions, causing severe injuries, fatalities, and extensive property damage. Incidents like the Imperial Sugar explosion tragically underscore this reality.

Operational Downtime: An explosion or fire can bring your entire operation to a halt for weeks or months, leading to massive financial losses and impacting supply chains.

Insurance & Liability: Proper DHAs can lead to lower insurance premiums and significantly reduce your company’s liability in the event of an incident. Many insurers, such as FM Global, prioritize facilities with demonstrated safety compliance.

SSI’s Comprehensive Dust Hazard Analysis Process

Our structured DHA methodology ensures a thorough and accurate assessment, providing actionable recommendations for enhanced safety and compliance. We follow a rigorous, multi-phase approach:

Phase 1: Data Collection & Site Evaluation

Our process begins with meticulous information gathering. This includes reviewing facility layouts, process flow diagrams, safety data sheets (SDS) for all materials, existing safety protocols, and previous hazard analyses. Our certified experts then conduct an in-depth on-site evaluation of your facility.

We’ll examine all areas where combustible dust may be present, including dust collectors, conveyer systems, storage silos, grinders, mixers, and associated ductwork. This phase also includes identifying potential ignition sources such as hot surfaces, sparks, static electricity, and open flames. We ensure comprehensive coverage, aligning with the principles of industrial hygiene risk assessment.

Phase 2: Combustible Dust Testing & Material Characterization

A crucial step often overlooked by less experienced providers, we partner with certified labs to accurately characterize your dust’s explosibility. This involves crucial tests to determine:

- Kst Value: The dust deflagration index, indicating the explosive severity. Learn more about the importance of Kst from NFPA research.

- Pmax: The maximum explosion pressure.

- MEC (Minimum Explosible Concentration): The lowest concentration of dust in air that can ignite.

- MIE (Minimum Ignition Energy): The lowest energy needed to ignite a dust cloud.

- Limiting Oxygen Concentration (LOC): The oxygen level below which an explosion cannot occur.

These precise data points are fundamental to designing effective explosion protection solutions.

Phase 3: Hazard Identification & Risk Evaluation

Leveraging gathered data and test results, our experts meticulously identify all potential deflagration hazards. We analyze:

- Process equipment where dust clouds or layers exist.

- Potential ignition sources (electrical, mechanical, static, hot work).

- Interconnected equipment that could propagate an explosion (e.g., ducts, cyclones, bins).

- Existing safeguards and their effectiveness.

We then evaluate the risk associated with each identified hazard, considering both the likelihood of an event and the severity of its consequences. This allows for prioritization of mitigation efforts as per recognized industry risk assessment guidelines.

Phase 4: Recommendations & Comprehensive DHA Report

The culmination of our analysis is a detailed, actionable DHA report. This comprehensive document includes:

- A clear summary of identified hazards and evaluated risks.

- Specific recommendations for mitigation strategies, including engineering controls (e.g., explosion venting, explosion suppression, explosion isolation), administrative controls (e.g., housekeeping, maintenance procedures), and personal protective equipment.

- Prioritization of recommendations based on risk level.

- Guidance for ongoing compliance and maintenance.

- All necessary documentation required by NFPA and OSHA.

This report serves as your roadmap to a safer, compliant facility. For details on how we manage project implementation, visit our Project Management page.

The “When”: DHA Frequency & Triggers for Re-Evaluation

According to NFPA 652, a Dust Hazard Analysis must be reviewed and updated at least every five years. However, certain events necessitate an earlier re-evaluation:

- Significant changes to processes or equipment.

- Introduction of new combustible materials.

- Changes in building occupancy or usage.

- Following a fire, explosion, or near-miss incident involving dust.

- Updates to relevant NFPA standards or OSHA regulations.

SSI can help you manage your DHA schedule and ensure timely updates, as part of our comprehensive service offerings.

Key Benefits of an SSI Dust Hazard Analysis

Partnering with SSI for your DHA delivers tangible benefits for your business:

Expert Guidance: Rely on SSI’s decades of experience in industrial explosion protection and fire safety.

Achieve NFPA & OSHA Compliance: Avoid penalties, safeguard your reputation, and demonstrate due diligence. Our assessments help you align with current OSHA workplace safety guidelines.

Enhanced Employee Safety: Protect your most valuable asset – your people – from the devastating effects of dust explosions. This aligns with broader workplace safety initiatives by NIOSH.

Minimize Business Interruption: Proactive identification and mitigation significantly reduce the risk of catastrophic events that lead to costly downtime.

Tailored, Cost-Effective Solutions: Our DHA informs precise recommendations, ensuring you invest in the most effective and appropriate explosion detection and control systems for your specific needs, such as spark detection.

Improved Insurance Standing: A completed DHA demonstrates a commitment to risk management, potentially leading to more favorable insurance rates and terms. Many insurers reference property risk management best practices.\

Industries We Serve for Dust Hazard Analysis

Any industry that processes or handles combustible dust needs a DHA. SSI provides expert services to a wide range of sectors, including:

- Textile Manufacturing

- Food Processing (e.g., flour, sugar, spices, cornstarch)

- Wood & Timber Products (e.g., sawdust, wood flour)

- Grain & Agriculture (e.g., mills, silos, feed production)

- Metalworking (e.g., aluminum, magnesium, titanium powders)

- Pharmaceutical & Chemical Manufacturing (e.g., active pharmaceutical ingredients, pigments)

- Plastics & 3D Printing (e.g., polymer powders)

- Energy & Biomass (e.g., coal dust, biomass pellets)

- Rubber & Tire Manufacturing

Frequently Asked Questions (FAQs) About Dust Hazard Analysis (DHA)

What is a Dust Hazard Analysis (DHA)?

A DHA is a systematic review of a facility’s processes and operations to identify where combustible dust hazards exist, evaluate the risks associated with those hazards, and recommend protective measures to mitigate explosion and fire risks. It’s a key requirement under NFPA standards, serving as the foundation for safe dust handling operations.

Who is required to perform a DHA?

Any facility that handles, generates, or processes combustible dusts, regardless of size, is typically required to perform a DHA under NFPA 652 and 660. This applies to a wide range of industrial sectors, as outlined by NFPA’s combustible dust guidance, spanning everything from food production to metal manufacturing.

How often does a DHA need to be updated?

NFPA 652 requires that a DHA be reviewed and updated at least every five (5) years. Additionally, any significant changes to processes, materials, or equipment within the facility should trigger an immediate re-evaluation of the DHA to ensure continued safety and compliance.

What are the consequences of not having a DHA?

Failing to conduct or maintain a DHA can result in severe OSHA fines, potential facility shutdowns, increased insurance premiums, and, most critically, an elevated risk of catastrophic dust explosions that can cause fatalities, injuries, and immense property damage. The Chemical Safety Board (CSB) frequently highlights these dangers through accident investigations.

What is the role of dust testing (Kst, Pmax) in a DHA?

Dust testing, including determination of Kst (explosion severity), Pmax (maximum explosion pressure), and MEC (minimum explosible concentration), is fundamental to a DHA. These values accurately characterize your dust’s explosibility, guiding the selection and design of appropriate protection methods like explosion vents or suppression systems. SSI partners with certified labs for precise combustible dust testing.

What kind of recommendations come out of a DHA?

DHA recommendations typically include a mix of engineering controls (e.g., installing explosion vents, suppression systems, isolation valves, proper grounding), administrative controls (e.g., enhanced housekeeping programs, hot work permits, training), and operational changes to reduce fire and explosion risks. These are tailored to your specific process and hazards.

How can SSI help with my DHA needs?

SSI offers end-to-end DHA services, from initial site assessment and material testing to comprehensive reporting and strategic recommendations. Our certified experts ensure your DHA is accurate, compliant, and actionable, providing the foundation for effective explosion detection and control solutions.

Dust Collector Fire Suppression Systems Information

Partner with SSI for Expert Dust Hazard Analysis Services

Don’t leave your facility vulnerable to the unseen dangers of combustible dust. A comprehensive, expert-led Dust Hazard Analysis is the crucial first step toward a safer, compliant, and continuously operating industrial environment. With decades of experience in industrial safety solutions, SSI provides peace of mind and robust protection.

Our commitment to excellence ensures your DHA is thorough, actionable, and aligned with the latest industry standards. We also offer ongoing service and maintenance for implemented systems to ensure their long-term effectiveness. For immediate assistance or to understand more about how we can support your safety objectives, you can always check our main FAQs page.

Contact SSI Today to schedule your Dust Hazard Analysis and take a definitive step towards mitigating combustible dust hazards. Our team is ready to provide a consultation specific to your facility’s unique needs.

Call us directly at 1-800-360-0687 to speak with a Dust Hazard Analysis expert.

You must be logged in to post a comment.