AIR SAMPLING SYSTEMS

When do you need to know there is a fire?

When do you need to know there is a fire?

When high value assets, equipment or irreplaceable items are at stake, early warning of a smoke or fire problem, is essential. Our air sampling or air monitoring equipment actively pulls in room air to a special chamber where it can detect the presence of particles that are created in the very early stages of combustion, even before smoke is visible. With the world’s widest sensitivity range, VESDA air monitoring produces multi-level warnings at the very early stage of an impending fire. This provides the valuable time necessary to initiate a flexible, appropriate response.

VESDA aspirating smoke and gas detectors buy the critical time needed to investigate an alarm and initiate an appropriate response to prevent injury, property damage or business disruption. These detectors have multi-level warnings and a wide range of sensitivity that does not degrade or change over time, so even extremely small levels of smoke or gas can be detected before a fire has time to escalate.

Which VESDA Model is right for you?

VESDA early warning detectors are available in a variety of models to accommodate a broad range of environments and applications. From small to very large, open spaces and from the cleanest to the dirtiest environments, VESDA multi-level detection provides reliable, high-sensitivity, very early warning detection.

VESDA-E

With up to 40% greater coverage in high airflow environments, the VESDA-E range of aspirating smoke detectors represent considerable CAPEX savings. Easier servicing and field replaceable architecture further reduce system OPEX. And of course, VESDA-E is completely compatible with existing VESDA systems.

- VESDA-E VEP – Flagship of the VESDA product line

- VESDA-E VES – Features individual pipe identification

- VESDA-E VEU – Features an ultra-wide sensitivity range

VESDA-E VEA

As a multi-channel addressable system, the VEA detector is able to divide a protected space into sampling locations, enabling the localization of potential sources of fire for faster incident response. The detectors are suitable for protection of areas where pinpoint location of fire events is essential, thus providing ideal fire detection solutions for healthcare, offices, education, retail, prisons and electrical cabinets.

VESDA Legacy Detectors

VESDA VLF

The VESDA VLF is available for two different size applications. The VLF 500 detector is a very early warning smoke detector designed to protect small, business-critical environments of less than 500 m2 (5,380 sq. ft.) For smaller applications the VLF-250 is designed to protect small, business-critical environments of less than 250 m2 (2,690 sq. ft.).

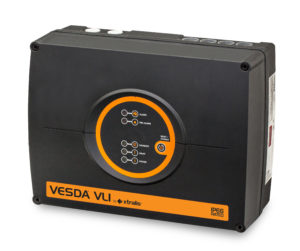

VESDA VLI

The VESDA VLI by Xtralis is an industry first early warning air-sampling smoke detection (ASD) system, designed to protect industrial applications and harsh environments of up to 20,000 sq. ft. (2,000m2). The VLI detector combines a fail-safe Intelligent Filter (patent pending) with an advanced clean-air barrier for optics protection allowing the use of absolute detection and a long detection chamber life without the need for re-calibration.

GAS DETECTION

VESDA Sensepoint XCL – Large Bore Aspirating Gas Detector

VESDA Sensepoint XCL – Large Bore by Xtralis is a gas detection solution that utilizes the ASD pipe network to deliver superior gas detection via multiple hole (multi-point) sampling. The combined solution provides reliable detection of gases for occupant protection and process monitoring while simultaneously ensuring protection against fire threats.

VESDA Sensepoint XCL – Micro Bore Aspirating Gas Detector

VESDA Sensepoint XCL – Micro Bore by Xtralis is used with VESDA-E VEA and provides early warning of the presence of gases for occupant protection and system monitoring while at the same time ensuring protection against fire threats.

BEAM DETECTION

OSID Open-Area Smoke Detection

OSID by Xtralis is a new technology designed specifically for open air environments such as Large, open spaces – airports, train stations, stadiums and shopping malls, enabling early detection and response to save lives and prevent service disruptions. OSID uses a sophisticated algorithm to map and compare the strength of infrared (IR) and ultraviolet (UV) light signals from detectors configured in the space. OSID also reduces the costs of installation and maintenance as the Emitter batteries have more than a five-year life.

VESDA is right for multiple applications.

Computer Rooms

Computer Rooms

VESDA detection is ideal for area that have high airflow. Conventional smoke detectors struggle to activate with high amounts of air passing through their chambers. VESDA detectors draw smoke from the aspirating pipe and the holes in the pipe collectively capture the air and draw it back to the VESDA detector. VESDA smoke detection is far more responsive than conventional smoke detectors. Learn more

Fire Suppression Applications

Fire Suppression Applications

VESDA detection with Fire Suppression is a fantastic combination. With ever increasing environmental responsibilities, it is essential that a fire suppression system should deploy unnecessarily. VESDA smoke detection use in conjunction with conventional smoke detection is a perfect match. Preferably VESDA detection samples the air across the return plenums of the air conditioning systems which provide primary smoke detection! An alert alarm can be raised and human intervention can prevent the gas from discharging!

Warehouses

Warehouses

VESDA smoke detection is a suitable replacement for conventional smoke detection where accessibility is limited. For example, VESDA detection will be better suited to a warehouse with smoke detectors situated at high levels. Conventional smoke detectors can become faulty and access equipment will need to be deployed, this can be extremely disruptive to operation and it is also dangerous. VESDA smoke detection eliminates this issue as the aspirating pipe work will be located at high levels and the VESDA detector will be located at accessible levels. Aspirating pipe will replace the smoke detectors at high level, with holes in the aspirating pipe replacing the smoke detectors. Learn more

Cold Storage

Cold Storage

VESDA smoke detection is commonly used where temperatures are not suitable for other types of smoke detection. For example, a cold room operating temperatures ranging from -4°F to 40° F, is an ideal environment for VESDA smoke detection. Cold temperatures will ice up the optical chambers of conventional smoke detectors rendering the system useless. VESDA detectors are located outside the cold environment, with aspirating pipe work located within the risk or outside the risk with capillary smoke sampling heads located within the risk! The cold air is then drawn to the VESDA smoke detector and is naturally heated before it arrives at the VESDA laser chamber. The condensation is collected at a condensate water trap and dry air arrives for sampling by the VESDA detector. In extreme cases air dryers may be needed, but in the most, are not required for the VESDA system!

Fire protection is important to your business. Finding the solutions to your fire protection needs is something we have been doing since 1983. Our customers have found that they can trust the experience, knowledge, honesty, integrity and ethics of SSI’s sales team. We invite you to contact one of the members of this team to discuss how SSI can protect your employee’s life safety and your valuable assets for the continued operation and success of your company. Contact us or call 1-800-360-0687 for a System Sales and Design Consultant to assist you with your needs.

You must be logged in to post a comment.