Industrial Explosion Protection Solutions That Meet Code and Save Lives

At Suppression Systems, we specialize in code-compliant explosion protection solutions that safeguard your people, processes, and production uptime. Whether you handle food ingredients, metal powders, wood dust, or chemicals, our engineered systems provide reliable protection against combustible dust explosions and deflagration events.

Our team of certified professionals offers full-system design, installation, and compliance documentation—ensuring your facility meets all requirements under NFPA 68, NFPA 69, NFPA 652/NFPA 660, and OSHA’s Combustible Dust NEP.

Our Core Explosion Protection Technologies

We provide turnkey systems that actively and passively mitigate explosions—designed to match your risk level, dust characteristics, and process requirements.

Explosion Suppression Systems (NFPA 69 Compliant)

Our high-speed explosion suppression systems detect and extinguish deflagrations within milliseconds—before damaging pressure builds.

Detection: Pressure and optical sensors continuously monitor your protected zones.

Control: Upon detection, suppression cannons discharge a chemical agent, arresting flame spread and pressure rise.

Ideal for: Enclosed equipment, indoor processes, silos, dust collectors, and where venting is not feasible.

Reduces pressure to safe levels (Pred)

Minimal process disruption

Compliant with NFPA 69

Learn more

Explosion Venting Systems (NFPA 68 Certified)

We offer deflagration venting panels and flameless vents designed to relieve pressure and redirect explosion forces safely. Learn more

Explosion Vent Panels: Designed to rupture at a calibrated pressure (Pstat), relieving internal blast force.

Flameless Vents: Arrest flame while allowing pressure release—perfect for indoor installations.

Proven passive protection

Maintenance-free

Compliant with NFPA 68

Explosion Isolation Systems

Prevent a single explosion from triggering a chain reaction throughout your process line.

Flap Isolation Valves: Mechanically close during a deflagration event, stopping pressure and flame travel.

Chemical Isolation: Rapid suppressant discharge into ducting to arrest flame propagation.

Fast-Acting Valves: Pinch or gate valves for material inlets.

Required by NFPA 69

Protects upstream/downstream equipment

Critical for interconnected equipment

Learn more

Spark Detection & Extinguishing Systems

Our spark detection systems detect ignition sources before they reach dust-laden zones—automatically extinguishing them with a targeted water spray.

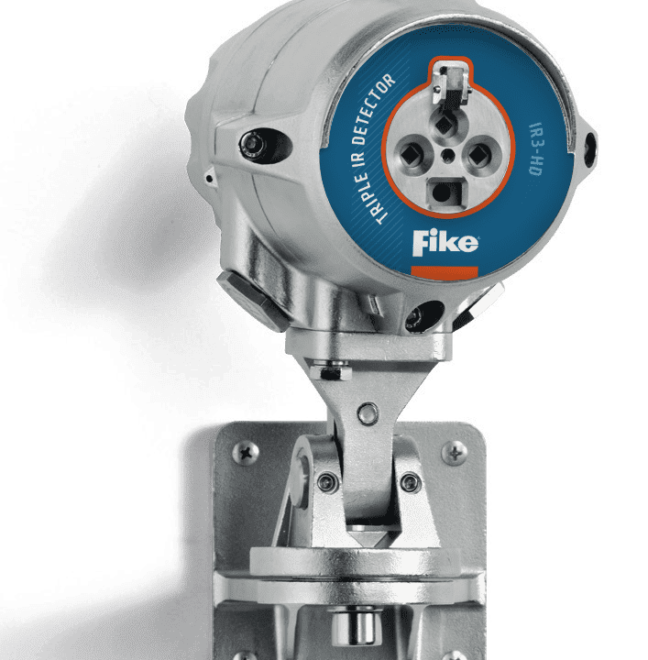

Infrared Sensors: Monitor ducts, chutes, or conveyors for sparks and embers.

Automatic Extinguishing: Deploys mist or water fog within milliseconds.

Prevents fires and explosions at the source

Recommended by NFPA 654

Ideal for woodworking, metal, and grain industries

Learn more

Combustible Dust Testing & Dust Hazard Analysis

We partner with certified labs to test your dust’s explosibility characteristics (Kst, Pmax, MEC), and our team delivers NFPA-compliant Dust Hazard Analyses for all dust-handling systems.

Identify all deflagration hazards in your process

Evaluate current controls and risks

Generate recommendations and compliance documentation

Required by NFPA 652 and NFPA 660

Avoid OSHA citations. Gain AHJ/insurer approval. Create a safer, compliant workplace.

If your company creates or handles dust during any phase of your process, you most likely are at risk for an explosion.

Over the past four years, the Combustible Dust Incident Database logged 960 fires, 357 explosions, 720 injuries and 126 fatalities from more than 40 countries. Two examples are:

Wood chipping fire in Ramseur, NC caused $2M in damages.

Paper product fire in Mooresville, NC caused $2M in damages. Combustible dust is a major concern for many.

Combustible dust explosions happen more frequently than many know. This video details the incidents over the past year. Combustible Dust Explosions

Here at SSI, by focusing on each and every application and process, we work with you to determine the most practical and cost effective method of protecting your process and facility. We then determine how to meet the most recent requirements of NFPA, OSHA, and your Insurance provider. But the first step is recognizing the risk, and understanding your options.

Learn more

Industries We Protect

Our explosion protection systems are tailored to each industry’s unique risks and standards. We serve:

Food Processing (sugar, flour, spices)

Wood & Timber (sawdust, sanding)

Grain & Agriculture (mills, silos, feed)

Metalworking (aluminum, magnesium)

Pharmaceutical & Chemical

Plastics & 3D Printing

Energy & Biomass

Aerospace & Defense

Battery Manufacturing & Recycling

Turnkey Solutions, Trusted Support

From site assessments and design engineering to system installation, commissioning, and post-install training—we handle it all.

With decades of experience, we help clients:

Achieve OSHA and NFPA compliance

Avoid unplanned downtime

Protect employees and infrastructure

Lower insurance premiums and meet audit requirements

Request a Site Evaluation or DHA

Let us help you protect your facility with a tailored explosion protection system.

Contact Us Now to schedule a consultation or request a Dust Hazard Analysis.

Frequently Asked Questions (FAQ)

What is a Dust Hazard Analysis (DHA)?

A DHA is a code-required review of your facility to identify where combustible dust hazards exist, evaluate your risk, and recommend protection strategies. It’s required every 5 years by NFPA 652/660.

When do I need an explosion vent or suppression system?

If your dust is explosive (Kst 0), and your process equipment is enclosed, you likely need some form of explosion protection system. NFPA 68 covers venting; NFPA 69 addresses suppression and isolation.

What industries require spark detection?

Woodworking, metal grinding, food processing, and grain handling often have upstream ignition sources. Spark detection systems eliminate these threats before they reach your dust collector.

Is explosion isolation always required?

Yes. NFPA 69 and NFPA 654 require isolation for any interconnected equipment.

How fast does suppression happen?

Our explosion suppression systems detect and extinguish an explosion in under 50 milliseconds—before pressure reaches destructive levels.

How do I know if my dust is explosive?

Combustible dust testing will determine this. If your material generates fine particles, you need a Kst/Pmax test to confirm risk and requirements.

At SSI, we will work with you to determine the most practical and cost-effective method of protecting your process and facility. We then determine how to meet the most recent requirements of NFPA, OSHA, and your Insurance provider. But the first step is recognizing the risk, and understanding your options.

To assist you with understanding Explosion Protection, please watch this video: What We Do – Explosion Protection or open this brochure from Fike.

To help you in determine how to proceed with an Explosion Protection System, we have made up a matrix: Explosion Protection Decision Matrix

From explosion venting to active explosion protection systems, Fike has the right high-performance products for all your sanitary, CIP/SIP and industrial applications. Learn more

The bottom line is, until you have implemented one or more of the techniques outlined above on your process, YOU ARE AT RISK! SSI can help you develop the most cost effective, practical and reliable explosion protection approach for your specific process. For over 20 years, SSI has been protecting properties like yours.

Explosion protection is important to your business. Finding the solutions to your explosion protection needs is something we have been doing since 2004. Our customers have found that they can trust the experience, knowledge, honesty, integrity and ethics of SSI’s sales team. We invite you to contact one of the members of this team to discuss how SSI can protect your employee’s life safety and your valuable assets for the continued operation and success of your company. Contact us or call 1-800-360-0687 for a System Sales and Design Consultant to perform a needs analysis at your facility.

You must be logged in to post a comment.