Optical Flame Detection: Ultra-Fast Response for High-Hazard Environments

Optical Flame Detectors sense the radiant energy emitted by open flames — detecting fires within milliseconds even when smoke is minimal. These line-of-sight detection systems are essential for areas where fuel vapors or flammable liquids can ignite rapidly, such as refineries, hangars, and chemical plants.

Detector Technologies: UV, UV/IR, and Triple IR (IR3)

Optical detection technology is engineered for rapid response and false alarm immunity. The right detector depends on your environment, fire type, and regulatory requirements.

Ultraviolet (UV) Flame Detectors

UV detectors sense short-wavelength radiation emitted at the instant of ignition. They provide the fastest response time (milliseconds) and can detect invisible flames such as hydrogen or alcohol fires. Best suited for clean, indoor environments or enclosed process areas.

Combined UV/IR Flame Detectors

UV/IR detectors require both ultraviolet and infrared signals to activate, greatly reducing false alarms from sunlight, welding, or hot equipment. They are the most common choice for general industrial applications requiring balanced performance.

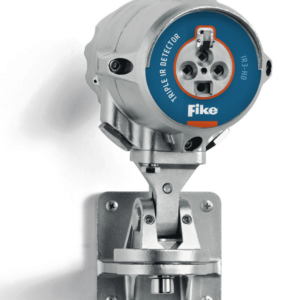

Triple Infrared (IR3) / Multi-Spectrum IR

IR3 detectors monitor three distinct infrared wavelengths to identify flame flicker patterns while rejecting reflections and ambient heat. This provides the highest immunity to false alarms, making IR3 ideal for refineries, fuel terminals, power plants, and outdoor process areas.

Mandatory Protection for High-Risk Applications

- Refineries & Chemical Plants: High-temperature, corrosive environments demand IR3 or Multi-Spectrum IR detectors to maintain safety and uptime.

- Aircraft Hangars & Maintenance Bays: Large open areas with potential fuel mist require ultra-fast optical detection per NFPA 409 and NFPA 72 standards.

- Tunnels & Conveyor Galleries: Where airflow and dust inhibit smoke detectors, optical systems provide dependable, early warning flame detection.

All optical flame detection designs must comply with NFPA 72 requirements for Radiant Energy-Sensing Fire Detectors. Each installation is evaluated based on fuel type, expected fire size, and detector field-of-view (FOV) to ensure complete coverage and code compliance.

Integrated Optical Detection & Suppression Solutions

Suppression Systems, Inc. integrates optical detection with Fike fire alarm control panels and clean-agent suppression systems for comprehensive protection in high-hazard industries.

Our engineers design and service UV/IR and IR3 systems throughout the East Coast, ensuring each project meets NFPA 72 and OSHA standards for flame detection and process safety.

- System design and optical coverage modeling

- Commissioning and field testing per NFPA 72

- Integration with suppression release and shutdown logic

Learn more about our complete Advanced Fire Detection offerings or contact our team for a site evaluation.