Home > Explosion Protection > Dust Hazard Analysis (DHA)

Dust Hazard Analysis (DHA)

A Dust Hazard Analysis is the foundation for combustible dust compliance and engineered protection decisions, venting, suppression, isolation, and ignition control all start here.

High intent, start here

Who this is for

- EHS and safety leaders completing or updating a combustible dust program

- Engineers selecting explosion protection for collectors, silos, and process equipment

- Plant and maintenance teams dealing with dust accumulation, ignition sources, or audit findings

- Owners responding to AHJ, insurer, corporate safety, or MOC triggers

Fast path

Call 1-800-360-0687 or request a DHA consultation. If you already have dust test data, send it, if you do not, SSI can help you start with combustible dust testing.

Corporate office: Suppression Systems Inc., 155 Nestle Way, Suite 104, Breinigsville, PA 18031

At a Glance

- A DHA is required by NFPA combustible dust standards for facilities that handle or generate combustible dust

- A DHA is not a generic checklist, it is a facility specific evaluation of where hazards exist, how they could ignite, and what safeguards are needed

- Dust testing (Kst, Pmax, MIE, MEC, and more) strengthens design decisions and helps avoid assumptions

- The output should be actionable, prioritized, and tied to real equipment, not generic statements

- SSI supports customers across Pennsylvania and the East Coast, within practical response range of Breinigsville, PA

Jump to:

What a DHA is | Requirements and standards | SSI DHA process | Dust testing and data | Design considerations | What you receive | Service area | FAQs | Resources

What is a Dust Hazard Analysis?

A Dust Hazard Analysis (DHA) is a structured review of your processes, equipment, building features, and operating practices to identify combustible dust fire and explosion hazards, then determine what safeguards are needed to reduce risk to an acceptable level.

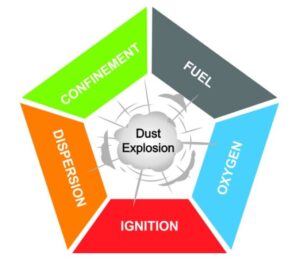

The key word is specific, a defensible DHA maps hazards to real equipment nodes, evaluates credible ignition sources, considers propagation paths, and verifies whether existing safeguards are adequate.

Why DHAs matter in the real world

- Secondary explosions can be larger than the first event when layered dust is dispersed into a cloud

- Propagation can occur through ducting, conveyors, and interconnected vessels without isolation

- Assumptions fail when material changes, moisture changes, particle size shifts, or process conditions drift

- Audits and enforcement typically focus on documentation, housekeeping, ignition controls, and whether safeguards match the hazards

Requirements and Standards

Most combustible dust programs anchor to NFPA requirements and OSHA enforcement priorities. Your AHJ, insurer, and corporate standards may add additional expectations.

Common standards referenced in DHAs

- NFPA 652, fundamentals and DHA requirement framework

- NFPA codes for dust related protection methods, when applicable (venting, prevention, and system design pathways)

- OSHA combustible dust resources, overview and hazard recognition

- OSHA NEP, CPL 03-00-008, national emphasis program focus for combustible dust inspections

- U.S. Chemical Safety Board, combustible dust, incident learnings and prevention emphasis

When a DHA needs review or update

Many facilities treat DHAs like a one time event. That is a mistake. A DHA should be reviewed on a defined cadence and whenever conditions change.

| Trigger | Why it matters |

|---|---|

| Process or equipment changes (MOC) | New ignition sources, new dust generation points, or new propagation pathways |

| Material changes, new products, new suppliers | Dust behavior can shift with particle size, moisture, additives, and blends |

| Building, ventilation, or collector modifications | Venting discharge, indoor hazards, and confinement conditions can change |

| Fire, deflagration, near miss, or recurring hot work | Your credible scenarios just became more credible |

| Audit findings, insurer requests, or AHJ questions | Documentation and safeguard adequacy are under scrutiny |

SSI’s Dust Hazard Analysis Process

SSI follows a practical, code-aware approach that connects documentation to real decisions. If you need a DHA that actually helps you choose safeguards, sequence upgrades, and defend decisions, this is the difference.

Phase 1, scope and site evaluation

- Confirm processes, materials, and equipment nodes where dust is generated, conveyed, collected, or stored

- Review drawings, flow paths, ventilation, housekeeping practices, and operating procedures

- Identify credible ignition sources, mechanical, electrical, thermal, static, and hot work related

Phase 2, dust data and explosibility inputs

If you do not have defensible data, you are guessing. SSI can coordinate combustible dust testing and help you connect results to design decisions.

Typical dust parameters used in DHA decisions

- Kst and Pmax, severity and pressure rise characteristics

- MIE, ignition sensitivity to sparks and static

- MEC, cloud explosibility concentration threshold

- Thermal behavior, ignition temperatures and smoldering concerns

- Additional tests as appropriate, based on material and process

Learn more about testing outputs and what they mean: Dust Explosibility Testing (Kst, Pmax, MIE) and Combustible Dust Testing 101.

Phase 3, hazard identification and risk evaluation

- Where can hazardous dust layers accumulate, where can hazardous clouds form

- What ignition sources are credible, how likely are they, and what prevents them

- How could flame and pressure propagate through connected systems

- Are existing safeguards appropriate, maintained, and documented

Phase 4, recommendations and a practical path forward

The output should not be a list of generic statements. It should tell you what to do, where, and why, in a way that supports both compliance and budget planning.

- Prioritized recommendations, focused first on credible high consequence scenarios

- A clear link between hazards and safeguards, including what standard or expectation drives the need

- Implementation planning support, including service and lifecycle considerations

Dust Testing and Characterization

Many facilities assume their dust is low risk because the product does not seem flammable. Dust changes the physics. Even materials that do not burn in larger form may be explosible when finely divided and dispersed, testing removes the guesswork.

Design Considerations After a DHA

A DHA often points to layered safeguards, not a single fix. The right mix depends on the dust, the equipment, occupancy, and whether venting to a safe location is possible.

Common safeguard categories

- Housekeeping and dust control, reduce layers and secondary explosion potential

- Ignition source control, static bonding and grounding, hot work controls, equipment maintenance

- Explosion venting, when vent discharge and indoor constraints are addressed (learn more)

- Explosion suppression, detect and stop deflagration early inside the vessel (learn more)

- Explosion isolation, prevent propagation through ducting and connected equipment (learn more)

- Spark detection and extinguishing, remove ignition sources before they reach collectors (learn more)

What You Receive From SSI

Your DHA deliverable should be usable. SSI focuses on producing documentation that supports decisions, implementation, and long term compliance, not just a report that sits on a shelf.

- A documented inventory of relevant equipment nodes and dust hazard locations

- Credible ignition source evaluation and existing safeguard review

- Prioritized recommendations, engineering controls and administrative controls

- Clear next step options, from testing to engineered protection selection

- Support for implementation planning, through SSI sales, installation, and service teams when needed

Common next steps after a DHA

- Complete or update dust testing to remove unknowns

- Select explosion protection for dust collectors, silos, and connected ducting

- Implement isolation to prevent propagation into buildings and adjacent equipment

- Improve ignition source controls and housekeeping, then document the program

If you need engineered protection next

SSI provides full lifecycle support, assessment, design, installation, project management, and service. Explore related pages: Dust Collector Explosion Protection Guide, Industrial Explosion Protection, Sales and Service, Project Management, Service.

Prefer to speak with an expert, call 1-800-360-0687 or contact SSI.

Service Area

SSI is headquartered in Breinigsville, Pennsylvania and supports combustible dust facilities across the Mid-Atlantic and Northeast, including many sites within a practical 12-hour drive for on-site evaluation, implementation, and ongoing service. For background on SSI, see About SSI.

Dust Hazard Analysis FAQs

Is a DHA required if we only have nuisance dust?

Maybe. The key question is whether the dust is combustible and whether it can accumulate or form a cloud under credible operating conditions. If you are unsure, start with dust characterization and testing.

Does OSHA require a DHA?

OSHA commonly references combustible dust hazards through enforcement directives and inspection focus areas. Many facilities align their combustible dust programs to NFPA requirements and use a DHA as the core documented hazard evaluation. See: OSHA combustible dust enforcement.

What is the role of dust testing in a DHA?

Testing provides defensible inputs for severity and ignition sensitivity. It helps engineering teams select safeguards based on real dust behavior instead of assumptions. Start here: Combustible Dust Testing.

What equipment is usually included in a DHA?

Any equipment where dust is generated, conveyed, collected, or stored may be included, collectors, ducts, cyclones, filters, silos, mixers, grinders, dryers, packaging, transfer points, and hidden accumulation zones above ceilings and on structural members.

Resources, Downloads, and References

Internal SSI resources

- Combustible Dust Testing

- Dust Explosibility Testing (Kst, Pmax, MIE)

- Dust Collector Explosion Protection, The Ultimate Guide

- Wood Dust Explosion Protection for East Coast Facilities

- Industrial Explosion Protection

Download

External authority references

Request a Dust Hazard Analysis Consultation

If you need a DHA that holds up to scrutiny and leads to clear engineered decisions, SSI can help. Call 1-800-360-0687 or contact us here.

Want proof and background first, review 10 Reasons to Choose SSI and What Our Clients Say.

Related SSI Pages

- Explosion Venting

- Explosion Venting vs Suppression, how to choose

- Explosion Suppression Systems

- Explosion Isolation

- Spark Detection Systems

- Fire and Explosion Protection FAQs